Allied Products for Process Equipments

"Innovative Sealing Solutions for Industry Excellence"

Our extensive experience in serving process industries and continuously evolving our product offerings to meet market demands. Beyond our standard range of sealing solutions, we have developed a variety of off-the-shelf technical products specifically designed for industrial applications. Our commitment to innovation drives us to tackle new challenges and create products that address the evolving needs of the industry.

Among our latest developments are specialized assemblies and components that enhance operational efficiency. Notable products include:

Chopper/Lump Breaker Assembly with Mechanical Seal: Engineered to effectively break down materials while ensuring a secure seal to prevent leaks and contamination.

Bottom Propeller Assembly with Mechanical Seal: Designed for reliable mixing and agitation processes, featuring robust seals to maintain performance under demanding conditions.

Stuffing Box for Pilot Equipment (Non-GMP): A practical solution for non-GMP applications, providing effective sealing in pilot equipment setups.

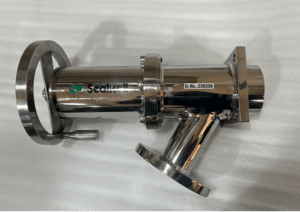

Discharge Valves for Pilot Equipment: Durable and efficient valves that ensure the smooth discharge of materials in various processes.

Lip Seals: Versatile sealing solutions that offer excellent resistance to wear and provide effective sealing for rotary and linear applications.

Bearing Bush: Precision-engineered components that support rotating shafts while minimizing friction and wear.

In order to support Process machine manufacturers (OEMs) SEALWELL has designed and developed complete Chopper/Lump breaker with inbuilt Mechanical Seal for Process Equipments like RVPD, RCVD, Nauta Dryers, Plough Shear Mixers. These comes as a factory single unit and can be directly install on machine pad and put into operations.

Specifications:

- Shaft Dia in Seal area: 30 mm, 40 mm & 50 mm

- MOC: SS 316, SS 316L, HAST C-276 & HAST C-22

- RPM: 960

- Motor: 1 HP, 1.5 HP, 2 HP, 3 HP, 5 HP & 10 HP (Motor is on client scope of supply)

In house developed Y-type discharge valves have immensely shown its acceptance for OEMs who are into manufacturing of Pilot or Lab model process equipments.

Mainly used in Pilot ANFDs. Sampling cum Discharge option can also be designed for Pilot equipment depending upon the capacity. Pneumatic cylinder can also be incorporated for atomization.

Specifications:

- MOC: SS 316, SS 316L, HAST C-276 & HAST C-22

- Size: 80 NB, 100 NB, 150 NB & 200 NB

- Sealings: Food Grade Silicone & FFKM

In line with Chopper assemblies, we have also developed Propellor Assy. with Mechanical Seals for bottom entry shafts. Blade is in client scope of supply and we maintain necessary space and tolerances for propellor fitment. Unit comes with in built Single & Double Mechanical Sealing arrangement depending upon the application.

Specifications:

- Shaft Dia in Seal area: 50 mm

- MOC: SS 316, SS 316L, HAST C-276 & HAST C-22

- RPM: 100 – 960

- Motor: 3 HP, 5 HP & 10 HP (Motor is on client scope of supply)

There are some areas and extreme conditions where conventional Mechanical Seal does not perform or there are frequent failures due to shaft misalignment, vibration or jerks.

These are best suited for applications like ETP and waste disposal where the media/sludge tends to break conventional Mechanical seal sealing arrangements.

Split Type Stuffing Box can be installed for Non-GMP application where shaft diameters are big and seal installation and removal is a big task.

For non critical application where vacuum sealing is to be done inside a rotating equipment, metallic lip seals can be used for these purposes.

Available in Single Lip, Dual and Multiple Lip options.

Lip MOC: PTFE, GFT & CFT

Bearings play a very pivotal role in rotating equipments. We can design and supply bearings bushes for imported rotating equipments by taking necessary measurement of equipment or can develop from samples. Suitable for dry and high temp. conditions.

MOC: Carbon, Brass, Silicon Carbide & Tungsten Carbide

All our newly developed products have been well-received in the market, and we continue to upgrade them based on feedback and evolving requirements. Our focus on quality and innovation ensures that we deliver reliable solutions that enhance operational performance in the process industries.

“Partnering with Mr Vaibhav Jain, Director of Sealwell Systems Pvt. Ltd., is a privilege we highly value.”