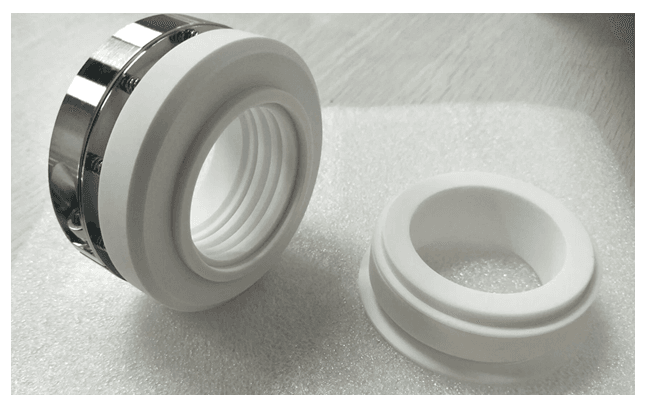

Mechanical Seal

"Sealing Strength, Engineered for Performance."

Mechanical seals are critical components in ensuring the efficiency and safety of a wide range of industrial applications, from pumps and compressors to mixers and turbines. Designed to prevent leaks, they provide a reliable seal between rotating and stationary parts, ensuring optimal performance and minimizing downtime.

At the heart of every high-performing machine is a reliable seal, and our products are designed to maximize longevity, reduce maintenance costs, and enhance operational safety. With a focus on innovation and engineering excellence, we deliver sealing solutions that ensure smooth, leak-free operations.

Vigor Impex provide mechanical seals are engineered with precision, as per client’s specifications, using durable materials to withstand the harshest conditions, including high pressures, extreme temperatures, and corrosive environments. Whether your operation involves chemical processing, oil and gas, or water treatment, our seals are built to handle the toughest challenges.

Choose our mechanical seals for industry-leading performance, dependability, and peace of mind because a secure seal means a more productive future.

"Partnering with Mr Vaibhav Jain, Director of Sealwell Systems Pvt. Ltd., is a privilege we highly value."