Rotary Joint

"Seamless Fluid Transfer for Rotating Machinery"

A rotary joint, also known as a rotary union or rotating union, is a vital mechanical device designed to facilitate the transfer of various fluids such as steam, water, oil, air, or coolant between stationary piping and rotating machinery. Rotary joints are crucial in industries where fluid needs to move in and out of rotating equipment without causing leaks or interruptions.

Function

The primary function of a rotary joint is to create a reliable seal between a stationary supply (such as a pipe) and a rotating part (such as a drum or cylinder). This allows the fluid to flow smoothly into the rotating component, ensuring efficient operation without leaks.

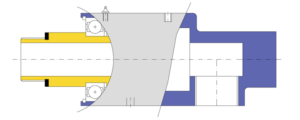

Components

Typically, a rotary joint comprises key parts such as a housing, shaft, bearings, and seals. The housing supports the entire unit, the shaft carries the fluid through the rotary joint, while the bearings ensure smooth rotation, and seals prevent any leakage during operation.

Applications

Rotary joints are widely used in various sectors, including manufacturing, paper production, food processing, and chemical industries. They play a key role in applications where fluids need to be transferred into rotating machinery, ensuring consistent and efficient performance.

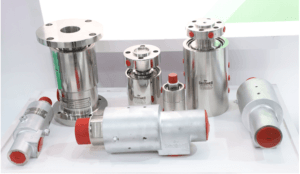

Types

Several types of rotary joints are available, each designed to handle different media, temperatures, and pressures, such as:

- Mono Flow (for hot/cold water)

- Dual Flow (for hot/cold water)

- High Temperature (for thermic fluid)

- Steam Application

- Multi-Port (for handling multiple fluids)

Rotary Joints are highly technical & specially designed devices which are used to transfer fluid from a stationary source, such as a supply pipe, into a rotating piece of machinery. It consists of Mechanical seal arrangement and bearing for smooth functioning.

In Mono Flow design the media follows a single path i.e. either it enters the equipment or comes back from the equipment.

Specifications:

- Design Pressure: 15 Kg/Cm2

- RPM: 10-100

- Design Temp.: 100 Deg. C.

- Size: 0.50” to 4.00”

In Dual Flow design media entering the equipment circulates and returns through syphon pipe from the same Rotary Joint

Specifications:

- Design Pressure: 15 Kg/Cm

- RPM: 10-100

- Design Temp.: 100 Deg. C.

- Size: 0.50” to 4.00”

Rotary Joints designed for high temp. oil (Thermic Fluid) circulation are used where extreme heat is to be transferred in equipment jacket or hollow shaft for heating purposes. Right selection of MOC for a specific temp. range is important for proper functioning and to achieve adequate life of Rotary Joint. In many cases, jacketed body is to be designed to counted the media heat.

Specifications:

- Design Pressure: 15 Kg/Cm2

- RPM: 10-100

- Design Temp.: 350 Deg. C.

- Size: 0.50” to 4.00

Steam being abrasive in nature makes a harsh impact on the sealing faces, elastomers and bearings. For Rotary Joints designed for steam application special care if to be taken so as to protect and select right MOC the internal parts so as to attain added life and performance

Specifications:

- Design Pressure: 15 Kg/Cm2

- RPM: 10-100

- Design Temp.: 280 Deg. C.

- Size: 0.50” to 4.00”

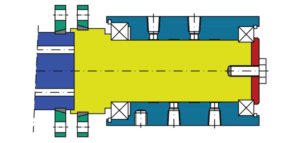

Tailor made Rotary Joints designed for special process equipments where multiple media is to be circulated in a particular system. The media can me Steam, Gas, Air, Water or Oil. All of these can be transferred to a system from the same Rotary Joint. These are designed depending on the Port size and media.

Specifications:

- Design Pressure: 20 Kg/Cm2

- RPM: 10-100

- Design Temp.: 250 Deg. C.

- Passage: 2-Way, 3-Way, 4-Way, 5 Way, 6-Way & 8 Way

- Port Size: 1/8”, 1/4″, 3/8” & 1/2”

Rotary joints are indispensable components in industrial systems, ensuring the smooth and leak-proof transfer of fluids under rotating conditions.

“Partnering with Mr Vaibhav Jain, Director of Sealwell Systems Pvt. Ltd., is a privilege we highly value.”